上海Front And Back Side Deburring And Chamfering

VSR660MS-W2S

Application Scope:

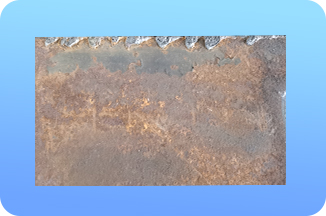

Flame (plasma) cutting of medium-thick steel sheet metal workpieces for de-slagging, deburring and chamfering.

Service Hotline:

400-8282-811

上海Front And Back Side Deburring And Chamfering

Application Scope:

Flame (plasma) cutting of medium-thick steel sheet metal workpieces for de-slagging, deburring and chamfering.

Service Hotline:

400-8282-811

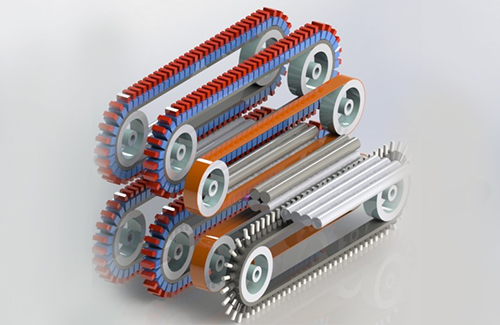

1. The steel shaft of the steel belt (series/disc) station is an elastic structure, which flexibly fits the end of the workpiece and runs at high speed to cut the slag and make the slag break and fall off; compared with the traditional belt sanding method, the slag removal is more thorough and clean, the cost of consumables is less than one tenth, and it is more energy-saving and environmental friendly; the belt runs at high speed through the elastic pressure wheel to fit the end of the workpiece to remove the fast mouth burr, and the belt flexibly touches the workpiece to reduce The abrasive belt is flexible to contact the workpiece to reduce the loss of abrasive belt;

2. The abrasive block is made of flexible material, which is flexible and close to the end of the workpiece and runs at high speed to cut the fast edge of the workpiece, and the soft abrasive block can reach into the groove hole of the workpiece to remove the inward turning burr and chamfer.

The equipment is developed and manufactured by Wanchuang independently, and Wanchuang has completely independent intellectual property rights, the whole machine has been authorized to patent, and imitation is prohibited.

Applicable Scope:Flame (plasma) cutting of medium-thick steel sheet metal workpieces for de-slagging, deburring and chamfering.

3VSR66OMS-W2S:Two-station combination structure. The first station flexible steel shaft spokes, the second station 1 group of flexible sanding belt, processing width ≤ 650mm, minimum processing 100 * 20mm, belt conveyor, speed 0-5m/min frequency adjustable, total power 16.5KW (including dust extractor), total weight 2.5T, appearance size L280 * W310 * H230cm.

General technology, parameters:Control system (human-machine interface, PLC programming control, one key to start and stop the equipment); grinding head speed (500-1000R/min), conveying speed (1-5m/min frequency adjustable); power supply voltage (three-phase five-wire, 380V, 50Hz); grinding head automatic lifting and positioning workpiece thickness, automatic compensation of abrasive loss, positioning thickness O-80mm adjustable.

The equipment supports customization and can be customized with other specifications.

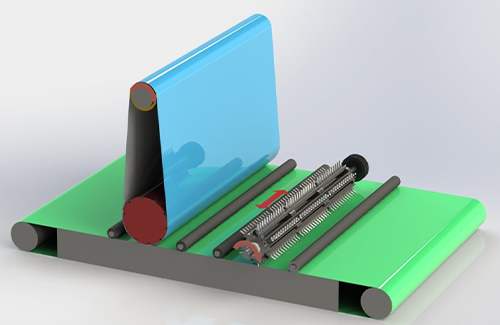

Steel shaft + abrasive belt schematic

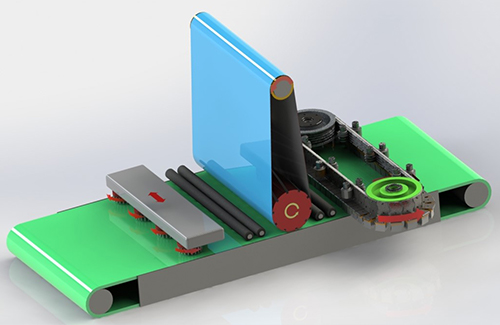

Steel shaft brush disc + abrasive belt + abrasive belt structure principle diagram

Front and back grinding structure schematic

Are you still looking for fully automatic polishing, grinding and deburring integration equipment?

Inquire